ENKA was awarded the contract in September 2011, for the electro-mechanical installation work on the Khabarovsk Refinery, in the Russian Federation.

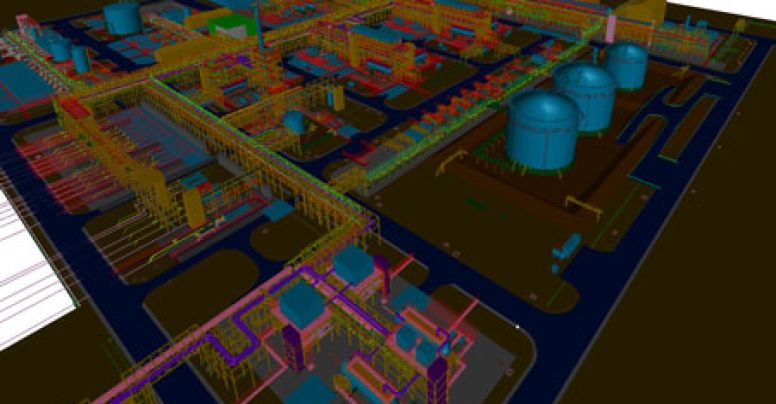

The Khabarovsk Refinery Hydroprocessing Project consists of a major expansion of the existing Khabarovsk refinery, to increase plant capacity, improve performance and address both Russian and international requirements for the reduction of the sulphur content of kerosene and diesel products.

The work included new combined Hydrocracking, Hydrotreating and Hydrogen Units. The associated utilities and offsites, together with the associated upgrades and infrastructure modifications and interconnecting pipe racks were also included.

The scope of the project also consisted of all related pre-commissioning activities, such as motor run tests, loop checks, coupling alignment and pump sealing.