ENKA’s wholly owned subsidiary Entrade GmbH, in a consortium formed together with Técnicas Reunidas and FCC Industrial, has signed an EPC (Engineering, Procurement and Construction) contract with the Hanseatic Energy Hub company for the Liquefied Natural Gas (LNG) Regasification Terminal to be built at the Stade Industrial Park situated on the banks of Elbe River, Lower Saxony, Germany.

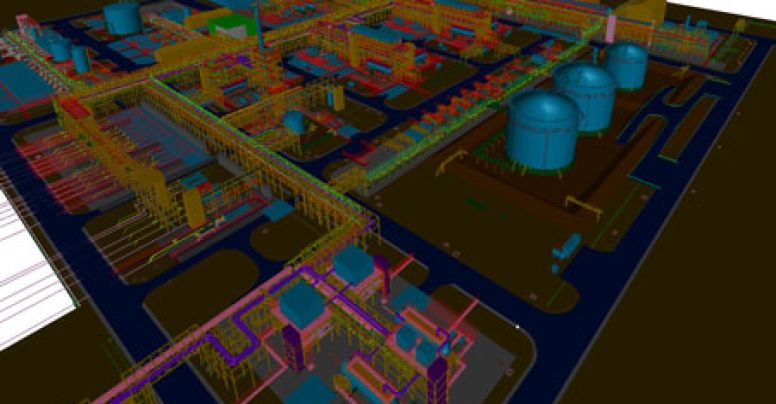

The contract is for the design and construction of a new storage and regasification terminal for liquified gases, featuring unloading facilities on a newly built modern energy port at Stade.

The land on which the facility will be built belongs to the large chemical company, Dow Chemicals, which is participating in the project as one of the development partners. The terminal will utilize Dow’s industrial waste heat and therefore will be able to regasify the gases without additional CO2 emissions.

The terminal is an important element of Germany’s current energy policy, as one of its main objectives is to diversify its natural gas supply with liquefied natural gas (LNG) and green gases while preparing for the market ramp-up of hydrogen.

The terminal, which will have a nominal annual capacity of 13.3 billion m3, involves a total investment of 1 billion Euros and the share of Entrade GmbH is approximately 25%.

Following the first phase of 5 months for preliminary and engineering works, the second phase, the main works, is planned to commence with the final investment decision to be taken by the Client.