ENKA was awarded a contract by ExxonMobil Iraq limited (EMIL) in July 2015 for a new oil processing facility, called Initial Oil Train (IOT), to increase production at its West Qurna 1 (WQ1) Oil Field in Iraq. The end-user of this new facility is Basrah Oil Company (BOC) of Iraq.

West Qurna is one of the largest oil fields in Iraq with an estimated 43 billion barrels of recoverable reserves. In January 2010, EMIL, an affiliate of Exxon Mobil Corporation, signed an agreement with BOC of Iraq Ministry of Oil to rehabilitate and redevelop the WQ1 field. Facility is located approximately 50 km north-west of Basrah in south-eastern Iraq. WQ1 is one of three segments of one large oil field complex located in southern Iraq that is bounded by the Rumaila Field to the south and the West Qurna II field to the north.

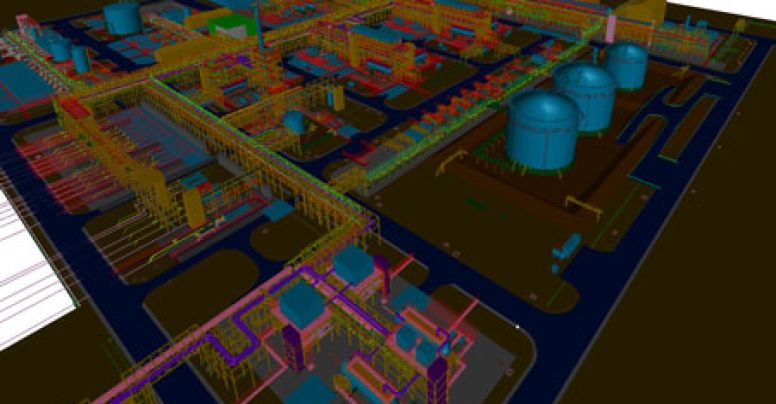

The facility, located in the province of Basrah, is designed to process full well stream fluids from the production wellhead area and separate them into associated gas, untreated produced water and stable product crude for export. The contract required modularization of the facility to the maximum possible extent with consideration of the logistics constraints.