Located 60 km north of Basra, in southern Iraq, Majnoon is one of the richest oil fields in the world with an estimated 38 billion barrels of oil in place. In January 2010, the Iraqi Ministry of Oil awarded Shell, Petronas and Missan a 20-year contract to provide technical assistance and increase oil production to a peak of 1.8 million barrels per day.

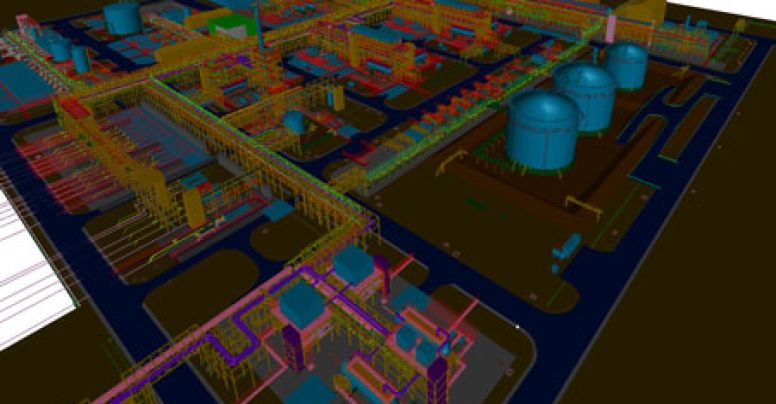

Shell Iraq Petroleum Development (Shell) B.V, envisaged a two phase development for the field. Phase I consisted of reaching First Commercial Production, while Phase II focused on the development of the full field. As part of the First Commercial Production, a new 100,000 bpd Central Processing Facility comprising 2x50k bpd trains, new well pads, various new wells and storage facilities, were planned. Crude exports from the processing facilities are transported through a pipeline, tied-in to the existing crude export pipeline.

In July 2011, for the early phase of the project, aimed at First Commercial Production, ENKA was awarded a contract by Shell for the mechanical, electrical and instrumentation construction work, for the new Central Processing Facility.