In the Iate 70’s MTA, Mineral lnvestigation and Research Institute discovered natural gas resources in Trakya, north-west of Türkiye. In early 80’s T.P.A.O., Turkish Petroleum Inc., determined reserves up to 15 billion m3 of natural gas in the same area and soon afterwards the State Planning Organization commenced feasibility studies regarding alternative usages of the exploited gas. The main alternatives were; to use natural gas as raw material in the existing and future fertilizer plants, to change Ambarlı Power Plant from fuel oil fired to natural gas fired, etc. Finally, it was decided to erect a combined cycle power plant to utilize the natural gas in the most favorable way and TEK, Turkish Electricity Authority called for an international turn-key tender.

ENKA – Alstom (former BBC) Consortium was awarded with the contract for 1,200 MW Natural Gas Combined Cycle Power Plant. Depending on the new natural gas source-Gas Pipeline between U.S.S.R. and Türkiye- decision for the 100 % extension of the plant was given and construction works were started in December 1986.

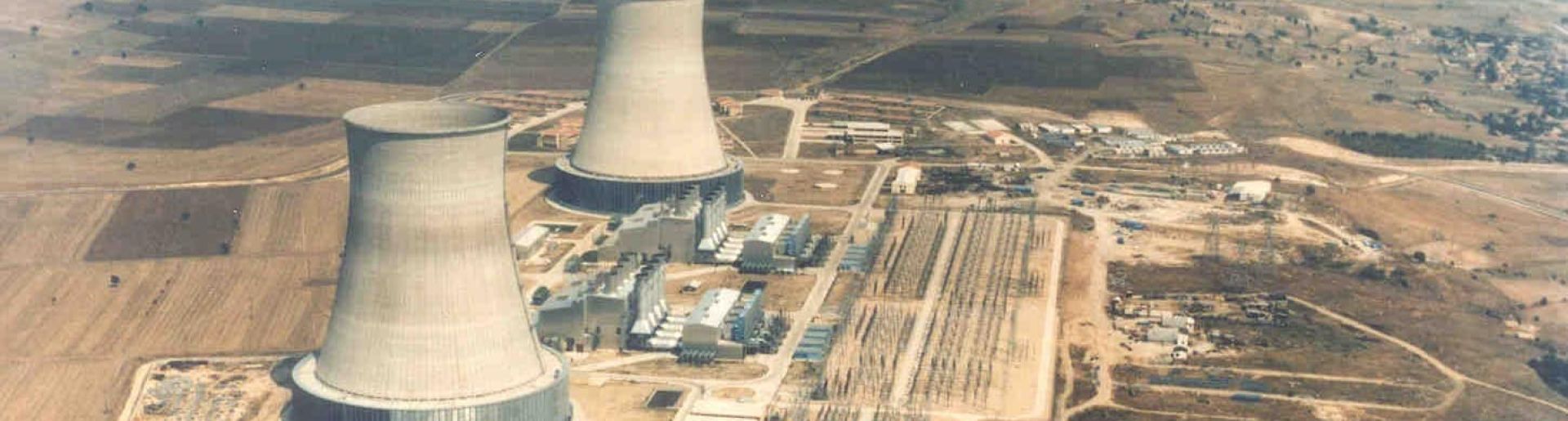

Trakya Natural Gas Combined Cycle Power Plant is the first of its type in Türkiye and produces 7,2 billion kWh electricity per year. The plant consists of 8 gas and 4 steam turbine each having an output of 100 MW and equipped with 2 Heller System Natural Draft Dry Cooling Tower each 135 m high. The plant has a high thermal efficiency (≈51 %) and specific installation cost (cost/kW) is much lower than the comparable conventional steam power plants.