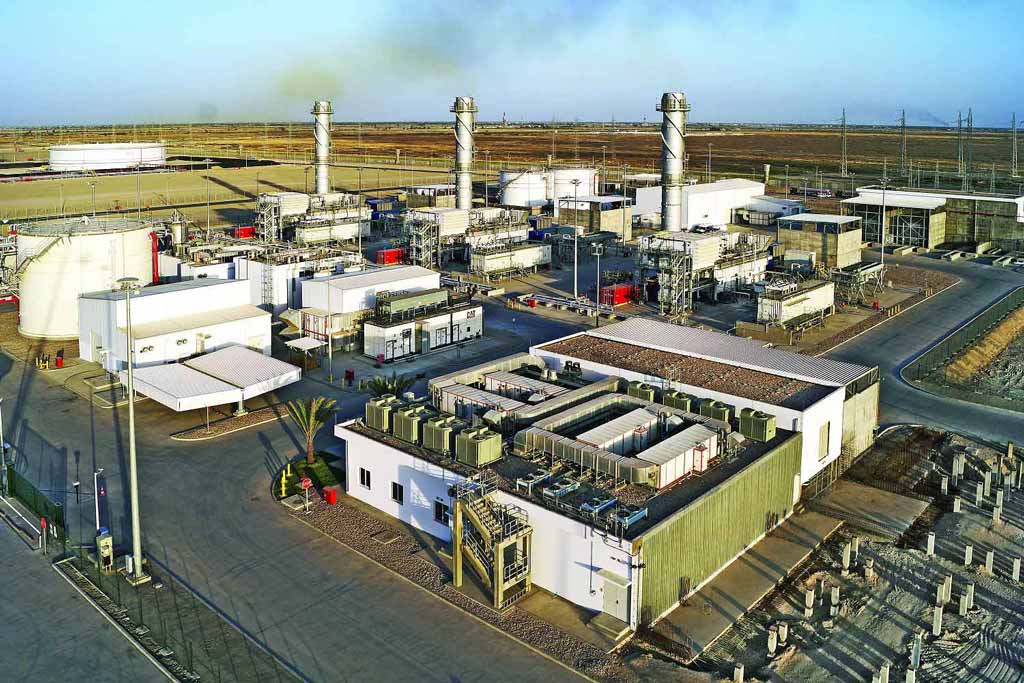

West Qurna-2 is a giant oil field in southern Iraq with recoverable reserves estimated at 13 billion barrels. In 2009, a consortium led by LUKOIL won a tender for the development of the field. As part of the oil field development, LUKOIL envisaged a Gas Turbine Power Plant to supply power to all oil production facilities.

ENKA was awarded the engineering, procurement, construction and commissioning contract for the 3 x 42 MW Simple Cycle Power Generation Plant and Power Distribution Project by LUKOIL in December 2011.

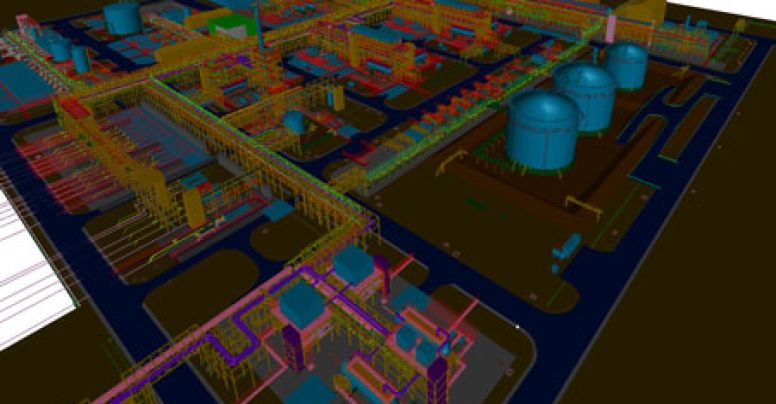

The specific content of the plant included; three (3) GE MS6001B Heavy Duty Dual Fuel Gas Turbine Generators – Simple Cycle – 42 MW each, a Fuel Gas Treatment Plant (45,000 Nm3/hour capacity) and a compression system included with fuel gas buffer storage, a liquid fuel unloading, storage and distribution system; 33kV/132kV GIS switchgear, power management system, a water treatment plant; fire fighting and protection systems, utilities’ networks; all associated balance of plant, buildings and infrastructure.

A major effort for the delivery of materials and civil, mechanical, and electrical and instrumentation construction works took place during 2013. The number of personnel employed by ENKA for the Project reached 1,000 people at its peak. Pre-commissioning and commissioning activities started in September 2013 and Mechanical Completion was accomplished by the end of the year. The project had passed the performance test and reliability runs by the end of May and the Provisional Acceptance Certificate was received in July, 2014.