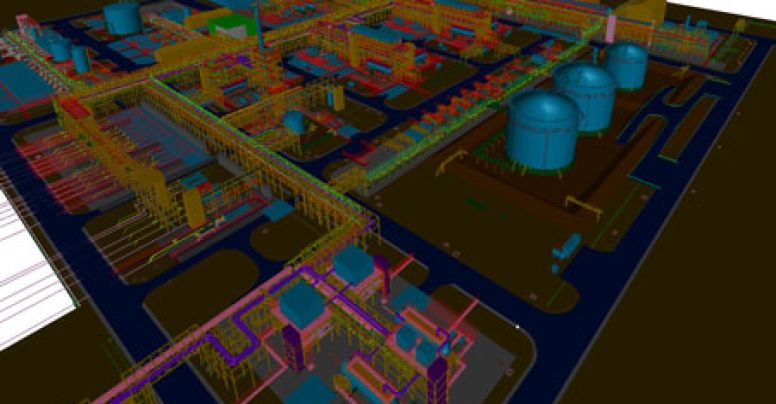

The main component of the Tengizchevroil’s Asset Development Project, the Second Generation Plant, one of the largest and most complex projects undertaken in the oil & gas industry, aimed to expand the crude oil production capacity of the Tengiz field by 12 mtpa and significantly increase the production of associated dry gas, propane, butane and saleable sulfur products.

Major new surface facilities included the crude stabilization, gas processing and sulfur recovery plants, together with all required utilities including a major power generation and power distribution facility.

ENKA and Bechtel successfully carried out the two main multi-discipline construction components for the Second Generation Plant Project under a single contract in Tengiz, including civil, structural, mechanical, piping fabrication and installation, electrical, instrumentation, insulation, painting and building works.