The consortium formed by our 100% owned subsidiary Entrade GmbH and Siemens Energy Global GmbH & Co. KG has signed a turnkey contract with the Ministry of Electricity of Iraq for the construction of a 921.8 MW natural gas combined cycle power plant in Nasiriyah, Iraq.

The plant is expected to become operational on July 31, 2029.

The plant will be constructed on a lump sum turnkey basis and the scope of the consortium includes engineering, procurement, construction and commissioning works for the power plant to have a safe and reliable operation in accordance with the EPC contract terms.

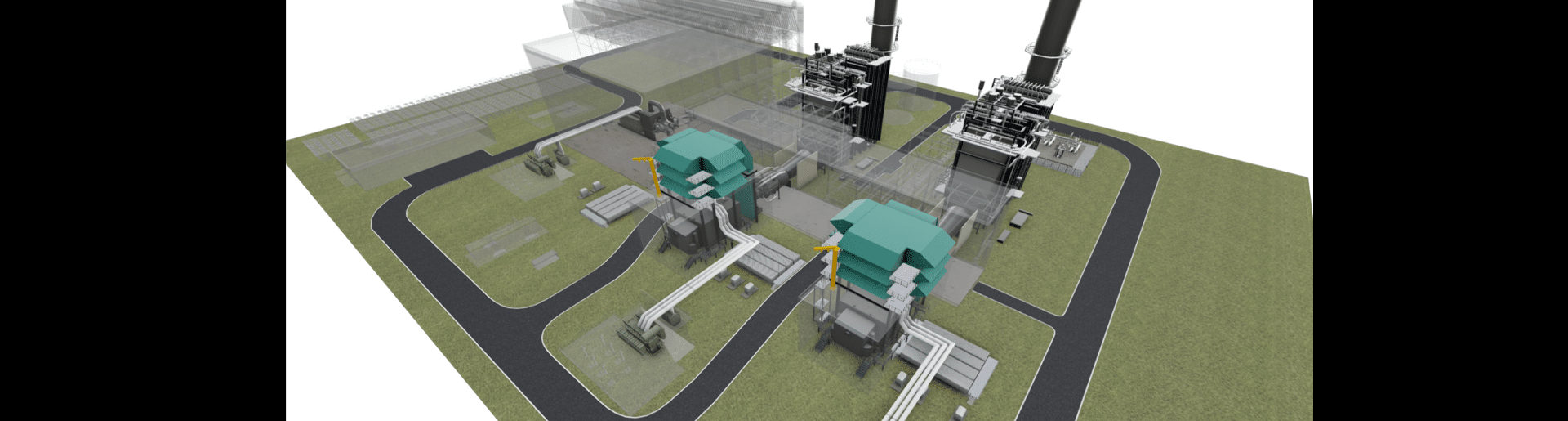

The project is based on a power island configuration for two (2) Siemens SGT5-4000F gas turbines, one (1) SST5-5000 steam turbine, three (3) air-cooled generators SGen5-2000P for the steam & gas turbines, and two (2) drum type heat recovery steam generators. In addition to power block equipment, air cooled condenser, 132 kV gas insulated switchgear, step-up transformers and other BoP mechanical and electrical equipment will also be provided.

The gas turbines are capable of using only natural gas and H2 as an optional future source.

The project helps to meet the urgent power needs of Iraq and improve the living conditions in the cities and surroundings.