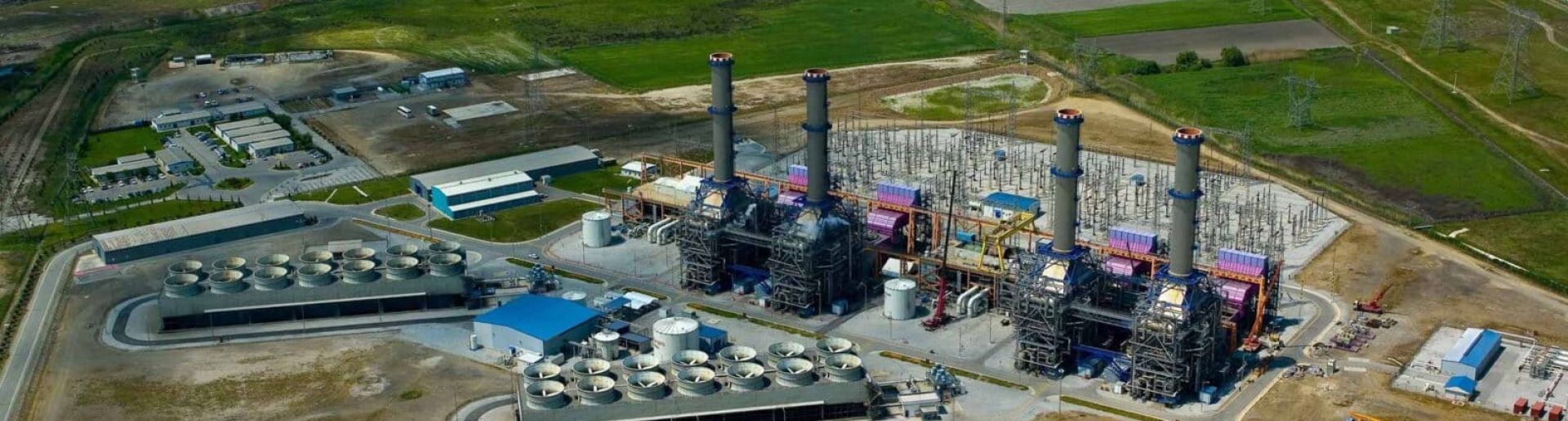

Following a Build-Own-Operate (BOO) tender in 1997, ENKA together with its partner InterGen was awarded the right to build and operate the İzmir Power Plant with a nominal capacity of 1,580 MW. ENKA with its joint venture partner Bechtel was the Turnkey EPC contractor for the plant.

ENKA Bechtel Joint Venture’s scope as the EPC contractor covered all the works including design, engineering, equipment supply, construction, commissioning and putting into operation this natural gas fired combined cycle power plant.

Five thousand workers have participated in both the manufacturing of components and construction of the İzmir power plant. During the construction phase, at the peak time, the various companies employ approximately 1,700 workers. A permanent technical & administration team has been now staffed for the plant Operation and Maintenance. Construction of the İzmir power plant was completed in 2003.

Since commercial operation began, ENKA has improved the infrastructure at the plants and invested in state-of-the art technology with the “Advanced Gas Path and DLN2.6+ Upgrade”. With this industry-leading technology, a fuel efficiency was improved, emission footprint was lowered and the operational flexibility and reliability of the power plants were enhanced.

With their collective annual generation capacity of 32 billion kilowatt-hours, they are capable of meeting 11% of Türkiye’s aggregate energy consumption as independent generation companies.